LTL Ltd is a manufacturing organisation producing made-to-order equipment for the construction industry, such as bespoke windows and doors. The Head of Operations has received four large orders and is considering the sequencing of production. Which of the following should the company do?

Which of the following aretypical objectives of Linear Programming (LP)?Select ALL that apply.

White Moon Ltd, amanufacturing organisation, is consideringoutsourcing transportation. What would be areason for doing this?

Which of the following principles considers the volume of work undertaken by a given resource within an organisation?

Maxi Ltd is a medium-sized manufacturing organisation in the automotive industry that creates engines for cars. It has traditionally worked well with its suppliers, with strong relationships and regular meetings. There are currently around 15 suppliers who provide parts to Maxi Ltd.

Due to changing customer demands, Maxi Ltd will, from next month, modify the manufacturing of some of its products. Product X is being made more environmentally friendly, with output of CO2 being reduced by 32%. The product will take longer to produce, but there will be no additional cost to customers for this.

Maxi ltd are considering outsourcing the manufacturing of Product Y as it is not a product which is routinely ordered by customers. This will allow Maxi Ltd to focus on other products which generate higher revenues for the company. The concern within the Board of Directorsis that if demand increases for this product, an outsourced company may not be able to cope with higher numbers of orders.

Product Z is an extremely popular item and oftentimes Maxi Ltd does not have the capacity to fulfil all orders. Consideration has been given to increasing the size of the factory, but this has been discarded as risky as demand is not guaranteed. The product has been available on the marketplace for a short amount of time and sales are continuing to increase, but the company believes this will soon plateau. To deal with current demand, the marketing team is working on campaigns to invite customers to make orders for this product at certain times of the year when product X is not being created in the factory. This means resources can be reallocated to the creation of product Z.

What is themain concernregarding the option to outsource the manufacturing of product Y?

The Improvement Gap Analysis can be utilised to manage trade-offs in operational strategy. Which of the following is measured by the IGA? Select ALL that apply.

Joy is a Senior Accountant at Big Fish Ltd. The organisation is a manufacturing company that specialises in sporting and camping goods such as tents, fishing rods, and archery equipment. These items are produced using imported raw materials from a variety of suppliers, many of whom arebased in low-cost countries. Joy is assessing the extent to which the organisation may be vulnerable to cost increases and fluctuating currency values. What is Joy completing?

Which of the following are disadvantages of thesmall-capacity strategyin capacity planning? SelectALLthat apply.

A car manufacturing organisation organises formal, regular meetings with itstier one suppliersfor the purpose of collaborating on improvements and changes to the final product. What is this arrangement known as?

Which of the following arecontract pricing arrangementsused to control costs?Select ALL that apply.

The operations department of ABC Ltd has recently launched a new product. The product is manufactured within a large factory and then sent to retailers for sale. The department has a system in place which details the components required for the product and the quantities required to fulfil customer demand. The system works online and links to other areas of the business including HR and finance.

So far, several large orders have been placed for the product from different retailers. The Chief Operations Officer (COO) has decided to programme the completion of the orders based on when the orders were placed. The benefit of this strategy is that it will give each customer a similar lead time. Thus far no buffer stock has been created as products are only created when orders are received.

Three teams are required to make the product and the product flows from team one to team two to team three, each team adding a component to the product. Unfortunately, team two are short staffed and are completing their work at a slower rate than the other two teams. This is a huge consideration for the COO as it will impact upon the capacity of the organisation.

The retailers have all signed contracts with ABC Ltd and the COO is extremely happy that they are long term contracts. Contract 1 is with retailer X and the price is set for three years. Contract 2 is with retailer Y and is a five year contract where the price will be reviewed annually in line with CPI. Contract 3 has a variable pricing mechanism based on the volume of products ordered.

What system is used by ABC Ltd?

Which of the following are Porter's strategies that can help an organisation create competitive advantage in the marketplace?Select ALL that apply

Risks are always present within organisational strategies, and it is important that they are assessed. Which of the following arestrategies for dealing with risk?

A cupcake manufacturing organisation uses a 'management by exception' technique when it comes to planning and control. What does this mean?

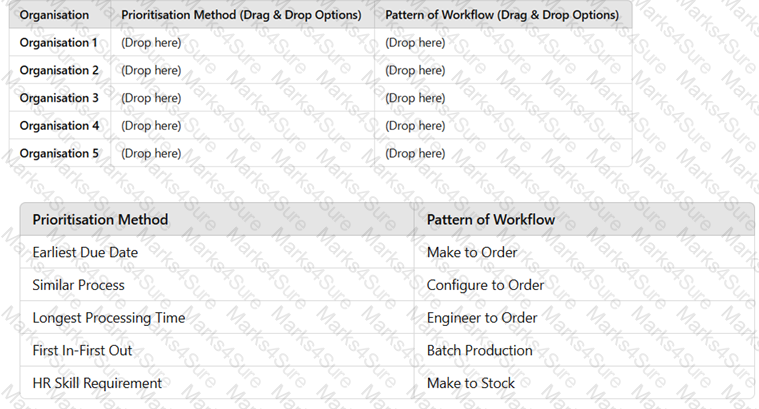

Scenario:

Five manufacturing organisations usedifferent order prioritisation methodsandworkflow patterns. Each company follows a uniquestrategy for order processingandworkflow structure.

For eachorganisation, select thecorrect Prioritisation MethodandPattern of Workflow.

Alexandra is the new Chief Procurement Officer at Wet Lettuce Incorporated, a manufacturing organisation that uses a tiered supply structure. She has asked to see the contracts with all thesuppliers and has been told that it is not common practice to have contracts with the full range of suppliers. What should Alexandra do?